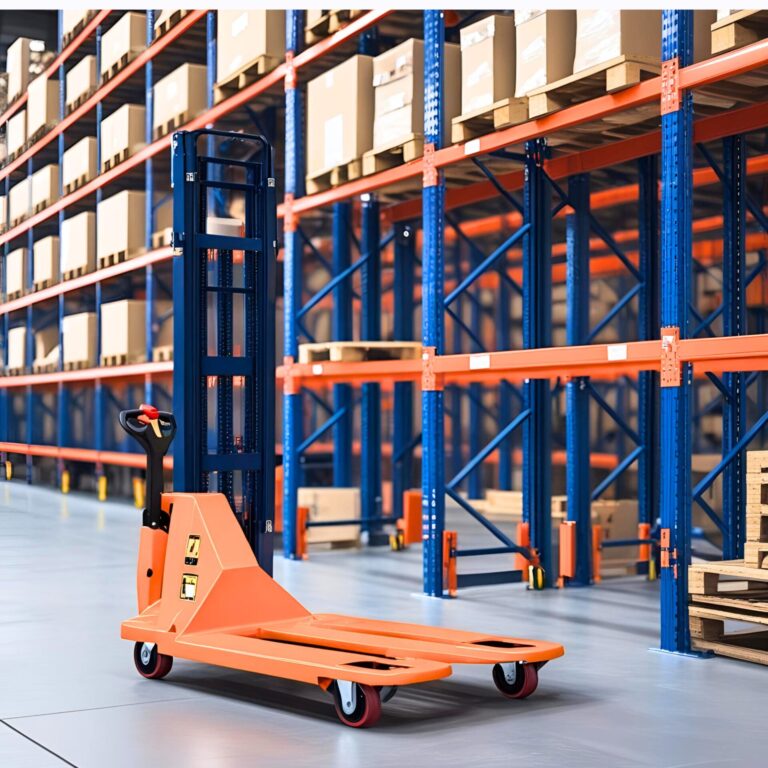

Optimize your warehouse operations in Dubai with advanced Pallet Racking systems. Maximize space, improve accessibility, and streamline inventory management for industries like retail, manufacturing, and logistics.

In this comprehensive guide, we will explore the benefits, types, and applications of pallet racking systems, as well as their role in improving warehouse efficiency.

What is a Pallet Racking?

A Pallet Racking System is a storage structure that uses vertical beams and horizontal shelves to hold goods stacked on pallets. These racks are designed to optimize vertical space, allowing businesses to store more inventory in less floor area.

The system ensures stability and safety for goods, even under heavy loads, and can be customized to suit specific business needs. From high-density configurations to selective access designs, pallet racking systems are adaptable to various warehouse operations.

Key Benefits

1. Space Optimization

One of the primary advantages of pallet racking systems is their ability to maximize warehouse space. By utilizing vertical space, businesses can store large quantities of inventory without expanding their facility’s footprint. This reduces the need for additional real estate and lowers overall operational costs.

2. Improved Accessibility

Different racking configurations are available to enhance accessibility. For example, selective racking systems allow direct access to individual pallets, making inventory retrieval faster and more efficient. Drive-in racks, on the other hand, are ideal for high-density storage, providing access from the front of the rack for bulk goods.

3. Enhanced Safety

Safety is a critical consideration in any warehouse, and pallet racking systems are designed to minimize risks. Features like weight capacity limits, protective barriers, and anti-collapse systems help prevent accidents and ensure goods remain securely stored.

4. Better Inventory Management

Pallet racking systems promote organized inventory management by keeping goods neatly arranged and easily accessible. This streamlines picking, packing, and shipping processes, reducing errors and increasing efficiency.

5. Customization and Flexibility

Every business has unique storage needs, and pallet racking systems are highly customizable. Whether you require high-density storage for bulk items or selective access for frequently rotated products, these systems can be tailored to your specific requirements.

Types of Pallet Racking

Pallet racking systems come in various configurations, each suited to different operational needs. Here are some of the most popular types:

1. Selective Pallet

The most common type of pallet racking, selective racks allow direct access to every pallet. This system is ideal for warehouses with a wide variety of products and frequent inventory turnover.

2. Drive-In Pallet

Drive-in racking is designed for high-density storage. Forklifts can drive directly into the racking structure, making it perfect for storing large quantities of similar items in a last-in, first-out (LIFO) arrangement.

3. Push-Back

This system uses inclined rails to store pallets. When a new pallet is loaded, the previous ones are pushed back. Push-back racking is ideal for storing a large number of items while maintaining easy access.

4. Pallet Flow

Using a gravity-fed system, pallet flow racks move goods from the back to the front, ensuring a first-in, first-out (FIFO) inventory flow. This is especially beneficial for perishable goods.

5. Cantilever

Although not specifically a pallet racking system, cantilever racking is often used in warehouses to store long, bulky items like pipes, timber, and steel beams.

Applications of Pallet Racking

1. Retail Industry

Retail warehouses benefit by storing a wide range of products in an organized manner. Selective racking is particularly useful for high inventory turnover in this sector.

2. Manufacturing Sector

Manufacturers often use pallet racks to store raw materials and finished goods. High-density systems like drive-in racking are ideal for bulk storage in this industry.

3. Logistics and Distribution

Logistics companies rely on efficient storage systems to handle large volumes of goods. Pallet racking systems improve sorting, picking, and shipping processes, enhancing overall operational efficiency.

4. Food and Beverage Industry

In industries with perishable goods, pallet flow racking ensures proper inventory rotation to prevent spoilage and maintain product freshness.

Why Choose Us for Pallet Racking Installation in Dubai?

For businesses in Dubai, implementing a pallet racking system can transform warehouse operations. Our team specializes in providing tailored racking solutions that maximize storage efficiency and meet your specific needs.

We offer:

- Professional Consultation: Assessing your space and recommending the best racking solution.

- Customized Solutions: Designing and installing systems that align with your operational goals.

- Expert Installation: Ensuring the system is set up safely and efficiently.

Maintaining Your Pallet Racking

To ensure the longevity and safety of your racking system, regular maintenance is crucial. Here are some tips:

- Routine Inspections: Check for any signs of damage, such as bent beams or cracked supports.

- Adhere to Weight Limits: Never exceed the recommended weight capacity of the racks.

- Clean and Organize: Keep the racks clean and free of debris to maintain safety and efficiency.

- Prompt Repairs: Address any damage immediately to prevent accidents.

FAQs about Pallet Racking

1. What types of products can be stored on pallet racks?

Pallet racks can store a wide range of products, including boxed goods, machinery, and perishable items, depending on the configuration.

2. How do I choose the right racking system for my warehouse?

Consider factors like inventory type, turnover rate, available space, and accessibility needs. Our experts can help you select the best system for your operations.

3. Are pallet racking systems safe?

Yes, when installed and maintained correctly, pallet racking systems are highly safe and include features like weight limits and protective barriers.

4. Can I expand my racking system as my business grows?

Absolutely! Pallet racking systems are highly modular and can be expanded or reconfigured as your needs evolve.

5. What is the lifespan of a pallet racking system?

With proper care and maintenance, these systems can last for many years. Regular inspections and prompt repairs will help extend their lifespan.

Conclusion

Pallet Racking Systems are a vital investment for businesses looking to optimize warehouse operations. They enhance space utilization, improve accessibility, and streamline inventory management, making them indispensable for modern warehouses.

If you’re looking for reliable pallet racking solutions in Dubai, contact us today to learn how we can help transform your storage space into a highly efficient and organized operation.